CDMOs like Particle Sciences hold the machines and staff set up to each develop and scale-up sterile lyophilization processes.

Process progress and high quality characteristics to the freeze-drying process in pharmaceuticals, biopharmaceuticals and nanomedicine supply: a point out-of-the-art overview Article Open obtain 07 November 2023 Key phrases

We hope to assistance the scientific Neighborhood to spare time, effort and hard work and revenue, whilst drawing consideration into the wide selection of alternatives made available from freeze drying in pre-scientific or essential investigate.

Latest improvements are reshaping the lyophilization landscape. Examples consist of automatic loading and unloading methods that lower the potential risk of contamination and human error; Sophisticated freeze-drying sensors and process analytical technologies (PAT) tools that make it possible for for far better Charge of the lyophilization process; controlled nucleation strategies that standardize the freezing step on the process; enhancements in energy efficiency and thus Price; tools and process control improvements that allow effective and predictable scalability from lab to industrial scale; integration with application and information analytics to assist better process understanding and optimization; plus the adoption of excellent by layout (QbD) concepts that permit much more robust and efficient lyophilization processes.

Sublimation warmth is not really wanted in the item surface area, but with the boundary of your ice Main that is certainly withdrawing in the centre in the product as drying proceeds.

Freeze dryers are invaluable resources for ensuring the preservation and structural integrity of perishable products. By eliminating water and solvents from the frozen product or service, they lock in the material's essence, guaranteeing its good quality and longevity.

Release the stress very slowly and gradually and punctiliously at the end of lyophilization by opening the valves little by little one after the other to circumvent more substantial airwaves blowing away small sample parts and spilling ice condensates on to the dry more info samples.

I would really like to join newsletters from Sartorius (Sartorius AG and its affiliated companies) primarily based of my individual pursuits.

The lyophilization process to get a protein-dependent drug may very well be optimized to protect its tertiary framework, While for a little molecule, the main target could be additional on blocking crystallization.

At JHS, you can find specific steps that go into preparing with the freeze dryer to begin the lyophilization process. It typically can take concerning 11 and sixteen several hours to finish the subsequent techniques:

Moreover, given that most reactions that will degrade products need a specific force stage to carry on, keeping a lowered force can further boost merchandise security and protection through freeze-drying.

In the course of this stage, the shaped water vapors are accumulated by a condenser, which leads to the vapors to tackle a good form.

The content material of our Web-site is always here accessible in English and partly in other languages. Choose your desired language and We're going to show you the content in that language, if accessible.

At the start of the principal drying stage, ice sublimation can take put in the solution surface area. Since the process carries on, the subliming surface area withdraws to the merchandise plus the ensuing vapor have to be carried out in the previously dried outer levels.

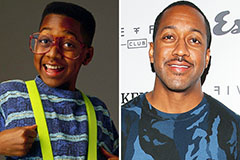

Jaleel White Then & Now!

Jaleel White Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now!